Tube Filling And Sealing Machine For High Viscosity Paste Cream

The rotary type plastic & laminated tubes paste filling and sealing machine is equipped with 1 filling head and tubes arranging feeder.

Suitable for: plastic composite tube, aluminum-plastic composite tubes and metal tube (optional).

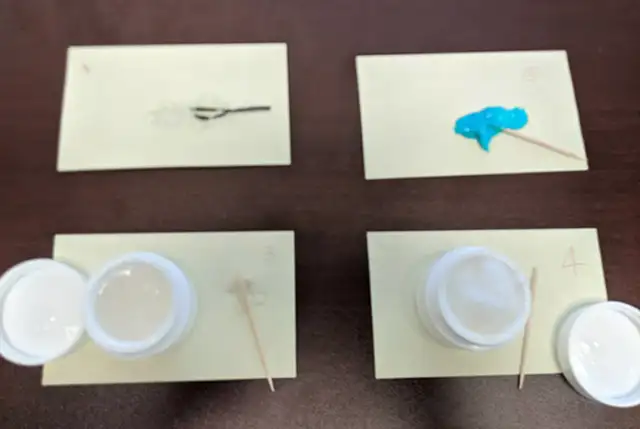

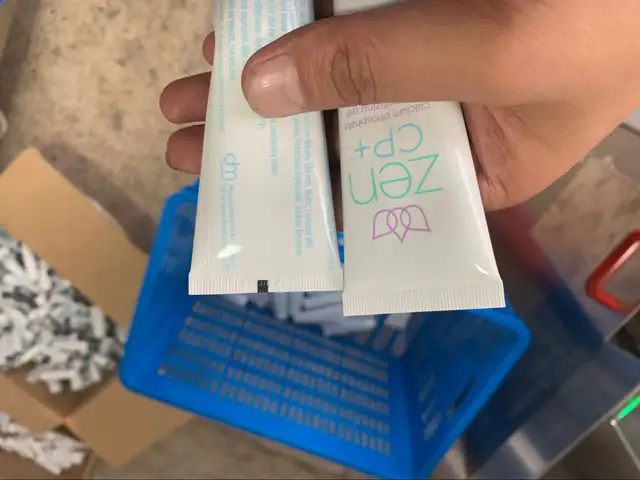

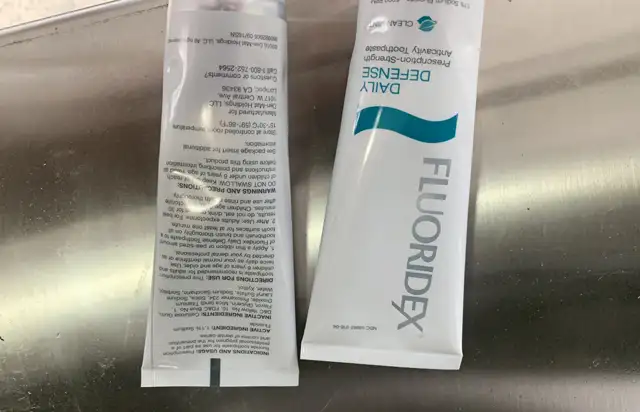

Applications of tubes filling and sealing machine:

Cosmetics, light industry (daily chemical), pharmaceutical, food and other industries, used for the selection of hoses for enterprise products, which can be used to fill materials such as ointments, creams, gels or viscosity fluids. Inside the tube, then fold the end of the hose and print the code to produce the finished product.

Main Feature

The transmission part is enclosed below the platform, which is safe and reliable, and has no pollution;

The filling and sealing part is installed in the semi-closed static-free outer frame visible cover above the platform, which is easy to observe, easy to operate and easy to maintain;

Stainless steel tact switch operating panel;

Slanted and straight-mounted tube silos, optional;

The curved armrest is equipped with a vacuum adsorption device. After the armrest interacts with the pressure tube device, the hose is fed into the upper tube workstation;

Photoelectric benchmarking workstation, with high-precision probe, stepper motor and other control hose pattern in the correct position;

At the end of the injection, the air blowing device blows off the paste tail;

No tube is not filled;

The sealing temperature is internally heated by the (Leister hot air gun), and the external cooling and cooling device is arranged;

The type code workstation automatically prints the word at the position required by the process;

The plastic manipulator cuts the tail of the hose into a right angle or a rounded corner for selection;

Failure alarm, overload shutdown;

Counting and quantitative downtime;

Technical Parameters

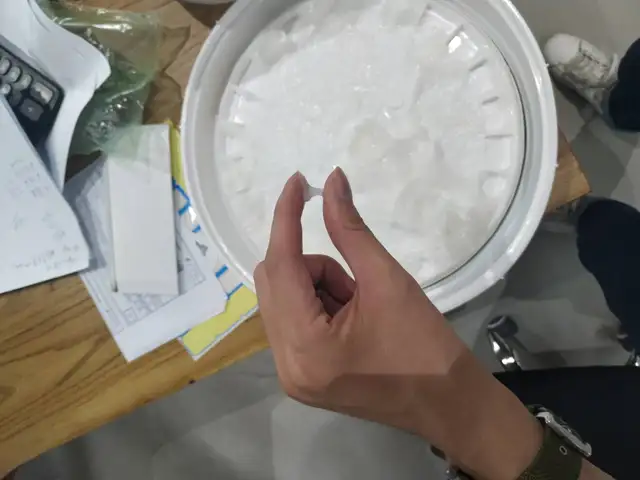

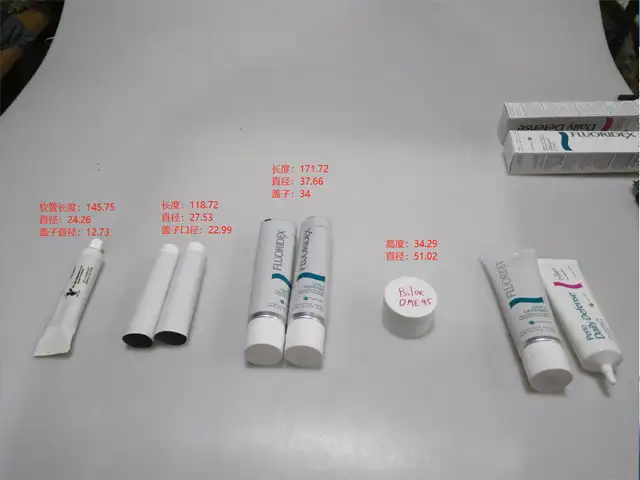

Tube materials: plastic tubes/laminated tubes/metal tubes

Filling volume: 5ml-250ml/tube(adjustable)

Filling precision: 1%(or less than)

Output capacity: 45 tubes per minute

Tube diameter: ø10mm-ø50mm

Max tube length: 220mm

Power source: 220v/380v/50-60hz

Air pressure: 0.55mpa-0.65mpa

Auxiliary motor: 1.1kw

Thermosealing power: 3.0kw

Overall dimension(lxwxh): 2000*900*1500

Weight of tubes filling sealing machine: 850kg

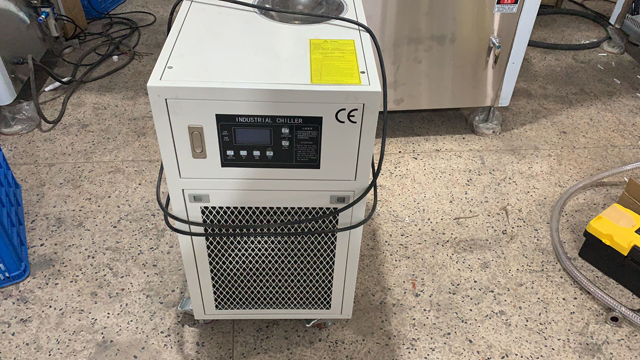

Auxiliary equipment water chiller for tubes filling and sealing machine:

Chiller water cycle

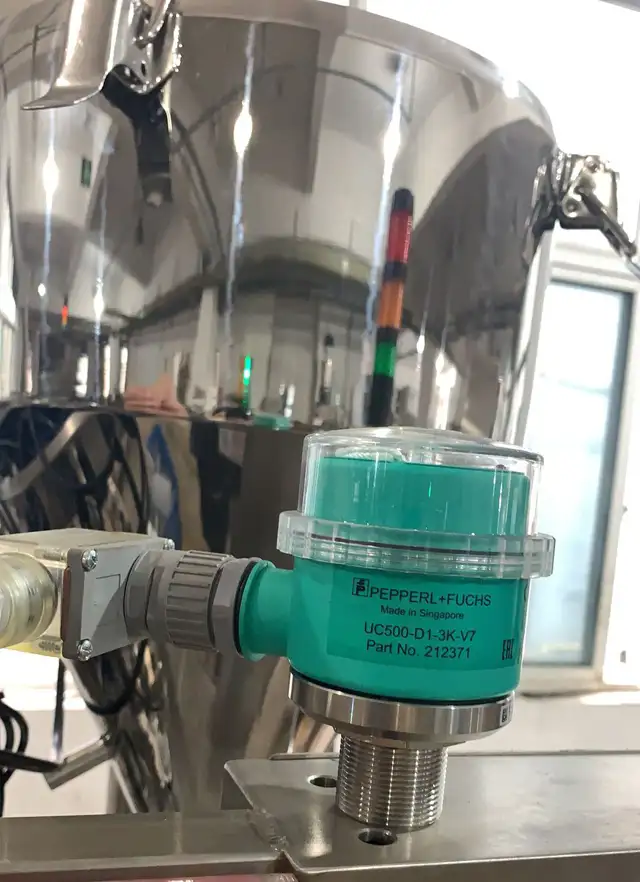

Microcomputer PLC control system, automatically control of whole units with error correcting operation system.

Original "SCHNEIDER" electrical components, and stability and durability guaranteed.

Built-in titanium tube water tank evaporator, avoid solid and other metal impurities.

Various models designed for different laser equipments. Water temperature tolerance at ±1℃(even±0.1℃) by precise digital control system. With push button operation, work normally without professional personnel.

Easy installation and compatible with equipments in any height.

High efficiency heat exchanger in special design, and static spraying casing with compact size.

Technical parameters of water chiller equipment:

Power of compressor: 0.95KW

Cooling capacity: 2.85KW

Pump power: 0.25KW

Refri gerant: R22

Power supply: 2P-220V/50HZ