Semi Automatic Ultrasonic Lotion Plastic Tube Filling Sealing Machine

Machine can be added with automatic tubes feeding system & safety cover(the machine will stop once the operator opens the door)

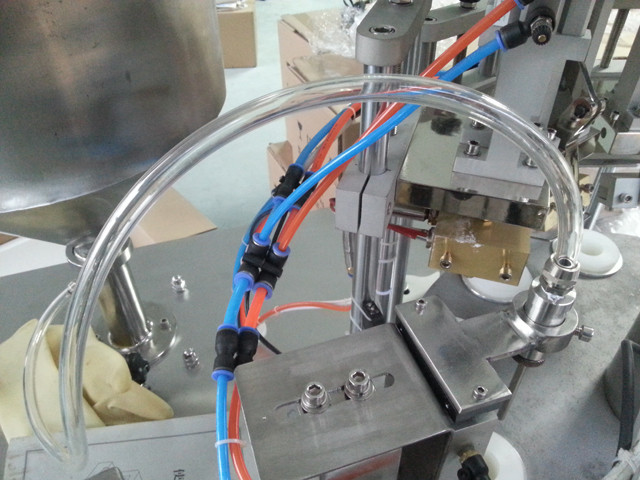

Semi automatic filling and sealing machine is especially designed for the products which has a small quantity and a special tube diameter. The machine has the virtue of the high speed filling and sealing machine, with a highly automatic operation and runs smoothly. It can be automatic tube filling, sealing, cutting and print date.the unique one-headed design is easier to clean. more convenient to the size changing and more simply to control. It is suitable be for medicine cream, toothpaste, cosmetics, glue, adhesive, ketchup and art palette industry especially.

Working Principle of filling sealing machines semi automatic

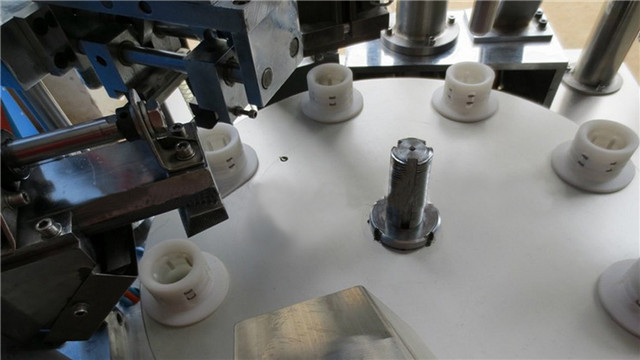

The machine is controlled by PLC and touch screen, the use of 12 equal station, the plastic hose in turn on the tube, the marks, filling, sealing, cutting and out of the tube. Insert the plastic hose into the socket, turn the function switch on, press the run button, the machine start periodic work under PLC control: rotary began to counterclockwise a workstation, stop rotating wheel after putting in place, then on the tube, the marks, filling, sealing, cutting and the tube body work.

(Note: the filling and sealing mechanism respectively equipped with infrared detection switch, must be detected under the condition of plastic hose will work).

When each end of the work, each agency reset. On the one end of the work cycle, the next one work cycle, the cycle. After a work cycle, plastic hose with rotary move to the next station, accordingly.

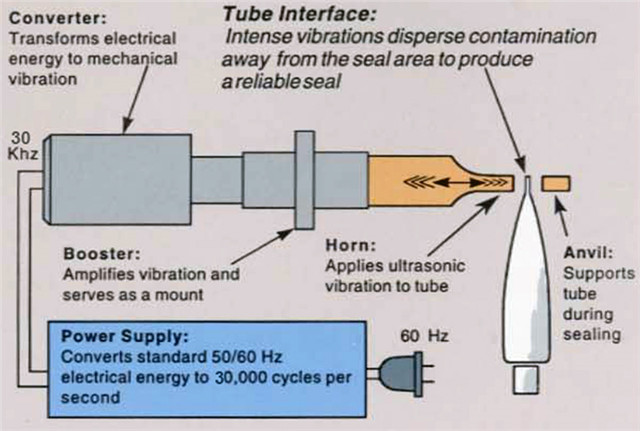

How ultrasonic sealing works

The ultrasonic tube sealer is designed to be mounted onto virtually all styles of filling machines. As the tube is advanced to the ultrasonic tube sealing station, a switch closes to initiate the weld cycle. Air is directed into cylinders to advance the weld anvil and ultrasonic horn towards the center line of the tube.

The tube is closed to a preset gap and held for the application of sonic energy.

An ultrasonic power supply takes the 50/60 Hz electrical energy and converts it to 30,000 cycles per second thorough a power oscillator.

This high frequency electrical energy is applied to the conversion which transforms the electrical current to high frequency mechanical vibrations.

The sonic energy causes the horn to vibrate against the tube end at 30,000 cycles per second.

The intense vibration disperses any contamination from the seal area and generates heat to bond the material.

The energy is then stopped and the tube is held closed for a brief time (typically .05 to .150 seconds).

Then the tube goes to the next station on the filling line. Typically cycle times range from 45 to 80 units per minute, depending on tube diameter and material.

Features

Plastic tube through the tube, the marks, filling, sealing, cutting and out of the tube, the machine packing job completion.

Covers and claddings made in 304 stainless, confirm GMP standard

Contact parts in SS 304

Positive filling nozzle. Pneumatic cut off system.( To avoid tailing problem)

No-tube No-fill /No tube No sealing Hot-air heating of tubes internally and cooling externally to avoid dent at the sealing are PLC control touch screen

Ferguson indexer

Panel box which is easy to access

Both side batch coding 12 characters at most.

Fill volume from 5ml up to 200 ml. with interchangeable pumps. 3ml to 30ml, 30ml to 100ml, & 100ml to 250ml

Tube diameter: min 10mm – max. 50mm.

Output up 1600 to 2,200 tubes per hour.

Tube counter

Easy adjustable sealing head

Main Technical Parameters

Voltage: 220v/50Hz/60Hz

Productivity: 20-30pcs/min

Dimension: 1220*920*1820mm(L*W*H)

Weight: 300kg

Filling Volume: 10-300ml

Tube Diameter: 10--60mm

Power: 2.0KW -3.3KW

Accuracy: ±1%

Material: Stainless steel 304

Control: PLC control system

Display: Touch screen display

Tube Height: 2-200(mm)