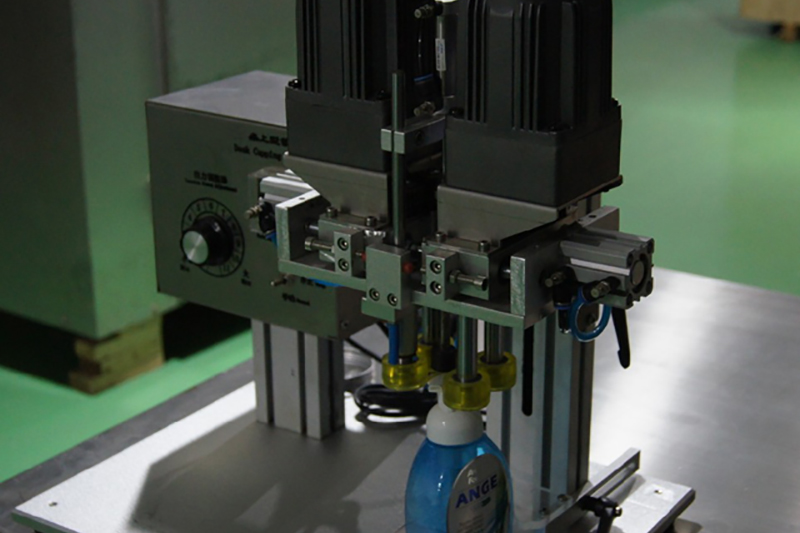

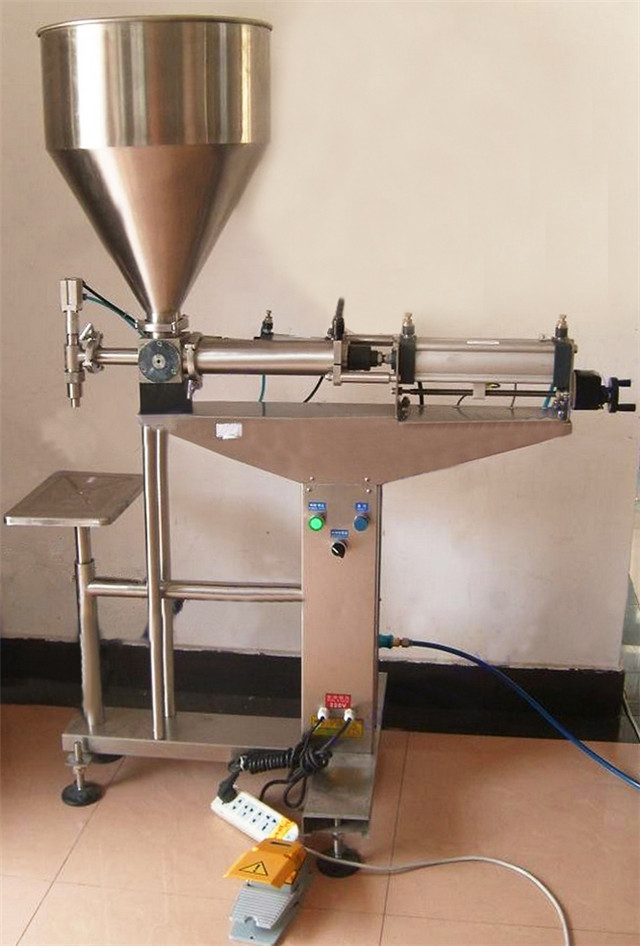

Desktop Semi Automatic Pneumatic Lotion Cream Filler Equipment

The desktop semi-pneumatic filling machine, mainly adopt the stainless steel, it have good resistant acid and alkali, certainly it is include the good corrosion. It can meet oil, sweet chili sauce, juice, injection,shampoo,washing-up liquid and paste etc, we can adjust the speed of filling when the machine working. At the same time, the machine adopt the vacuum recovery or moment closure methods, it is stop the liquid dripped.

It is really the good machine for clients choice.

Technical Parameters

Model: VK-LC04-100

Range of fill(ML): 10-100

Capacity(BPM): 10-17

Voltage(V) /power: 220/20w

Frequency(HZ): 50/60

Weight(KG): 35

Size of machine(MM): 980*550*1200

Model: VK-LC04-250

Range of fill(ML): 60-250

Capacity(BPM): 7-12

Voltage(V) /power: 220/20w

Frequency(HZ): 50/60

Weight(KG): 38

Size of machine(MM): 1000*500*1100

Model: VK-LC04-1000

Range of fill(ML): 250-1000

Capacity(BPM): 6-10

Voltage(V) /power: 220/20w

Frequency(HZ): 50/60

Weight(KG): 47

Size of machine(MM): 1100*550*1300

Model: VK-LC04-2000

Range of fill(ML): 500-2000

Capacity(BPM): 6-10

Voltage(V) /power: 220/20w

Frequency(HZ): 50/60

Weight(KG): 55

Size of machine(MM): 1650*700*1200

Features

1. Machine made of stainless steel, material touched part is SS 304 or 316L.

2. It's piston filler, with high filling accuracy.

3. Pneumatic parts adopt AIRTAC brand.

4. With two types: Bench-top (without stand) / Vertical type(with stand)

5. Filling Range: 20-5000ml (Can custom according to the requirements)

6. With simple structure, easy to operate and maintain.

7. Working Speed: 0-60 PCS/Min

Required Details offered from your side:

(1) What kind material will be filled? Liquid or viscosity?

(2) The filling range: the maximum filling quantity, and minimum filling quantity?

(3) The character of the material, if it's with acid or corrosion?

Optional Accessories

a) Needle filling head: Suitable for small diameter hose packaging bottles and filling. Diameter of the needle portion, the length can customize the specific dimensions of the container.

b) Ball Control System: suitable for different viscosity and contains particles of materials, and can solve the high pressure feed pressures

c) Hopper: We recommend filling high viscosity product configuration to achieve better filling effect.

d) Lift filling system: when filling filling volume and filling speed according to the need to adjust the lift cylinder lifting speed, so that the filling head as the temperature increased level in order to achieve the purpose of anti-foaming.